3Delight Metal is a physically plausible material that allows rendering of a whole range of metallic surfaces. This materials differs from other metal material in other renderers in many aspects:

- User friendly parameters such as reflectivity and edge tint instead of complex, difficult to understand index of refraction.

- Ability to render coated metals.

- Ability to render tempered metals. This effect is highly realistic and can render real life tempered metals faithfully.

The 3Delight Metal material has three main groups of parameters:

Coating, Base Layer, Reflection Anisotropy and Bump.

Parameters Description

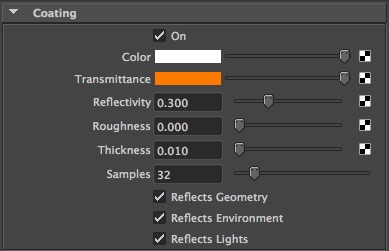

Coating | |||||||

|---|---|---|---|---|---|---|---|

On | Enables or disables the coating feature.

| ||||||

Color | This sets the color of the coating. This means that the color reflected by the coating will be tinted by this quantity.

| ||||||

Transmittance | Sets the colouring of the medium that makes up the coating. Light bouncing from the underlying metal will be tinted by this quantity. Thickness of the coating, described below, will affect how much transmittance color will be visible.

| ||||||

Reflectivity | Sets the ratio of light that bounces back when coming from a normal incident angle. For realistic coatings, this quantity should be kept low (only conductors have high reflectivity at normal incidence)

| ||||||

Roughness | Sets the roughness of the coating.

| ||||||

Thickness | Specifies the thickness of the coating. Thicker coatings will show more transmittance colour.

|

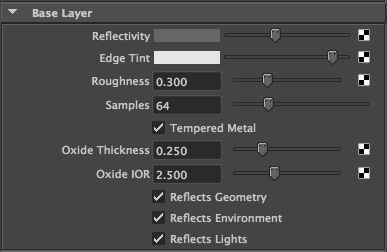

Base Layer | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Reflectivity | Describes the reflectivity at normal incident angle. This quantity, along with the edge tint below, completely describes physical metal characteristics.

| ||||||||

Edge Tint | Describes how light is tinted at grazing angles.

| ||||||||

Roughness | Describes metal roughness.

| ||||||||

Tempered Metal | Enables or disables tempering.

| ||||||||

Oxide Thickness | The thickness of the oxide layer, in micrometers.

| ||||||||

Oxide IOR | IOR of the oxide. Depends on the metal being rendered. Note that the Presets will automatically set this quantity to the correct value. For example, for iron,

|

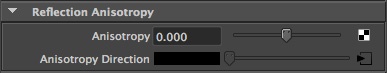

Reflection Anisotropy | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Anisotropy |

| ||||||||

Anisotropy Direction |

Each channel in the bitmap corresponds to a spatial dimension (X, Y and Z). These spatial dimensions are relative to a varying coordinate system based on the derivatives of position with respect to texture coordinates. Individual components for any direction should be in the range [–1, 1]. But to be encoded into an RGB texture with 8 bits per component, they are mapped into the range [0, 1]. So the XYZ (0, 0, –1) will be remapped to the RGB (0.5, 0.5, 0) values. It's also possible to use an angle texture to convert the direction to a color.

|

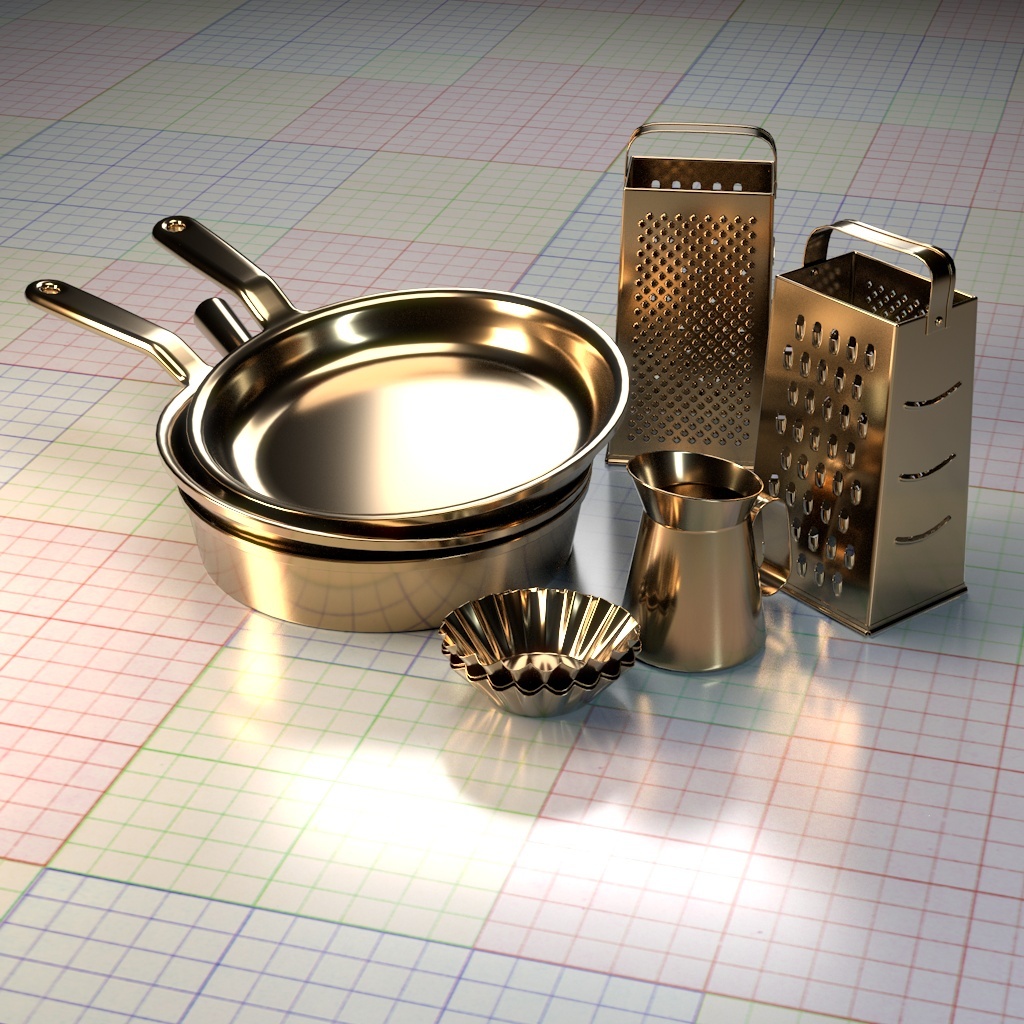

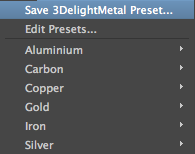

Example Presets

Main metals are accessible through the Presets menu.

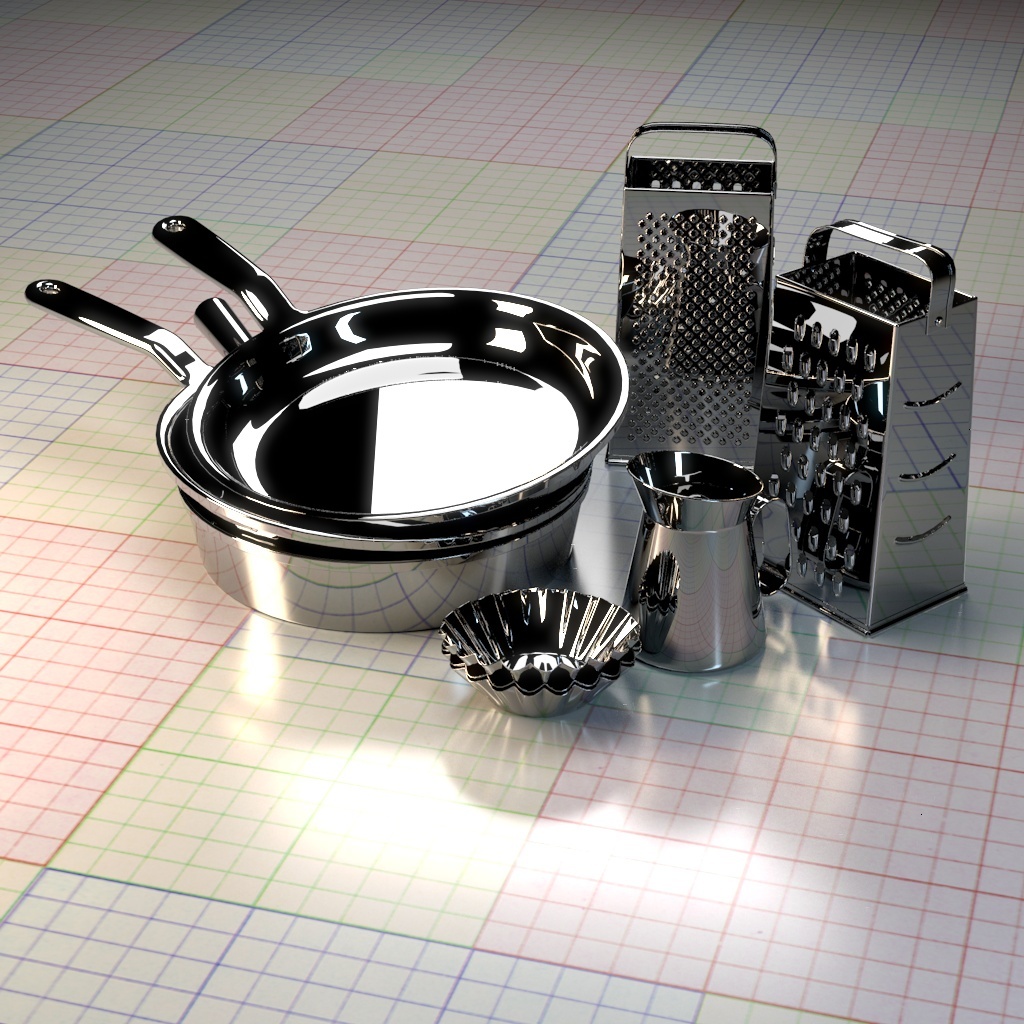

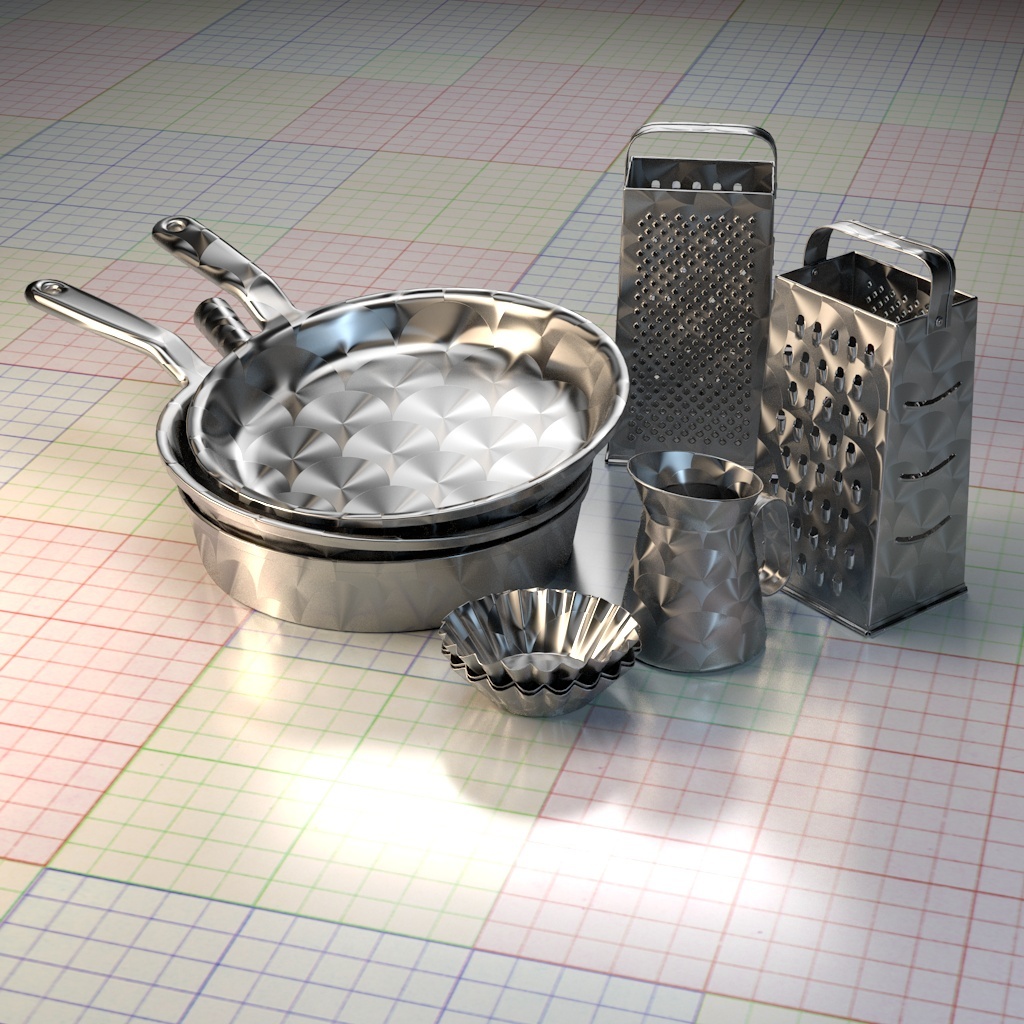

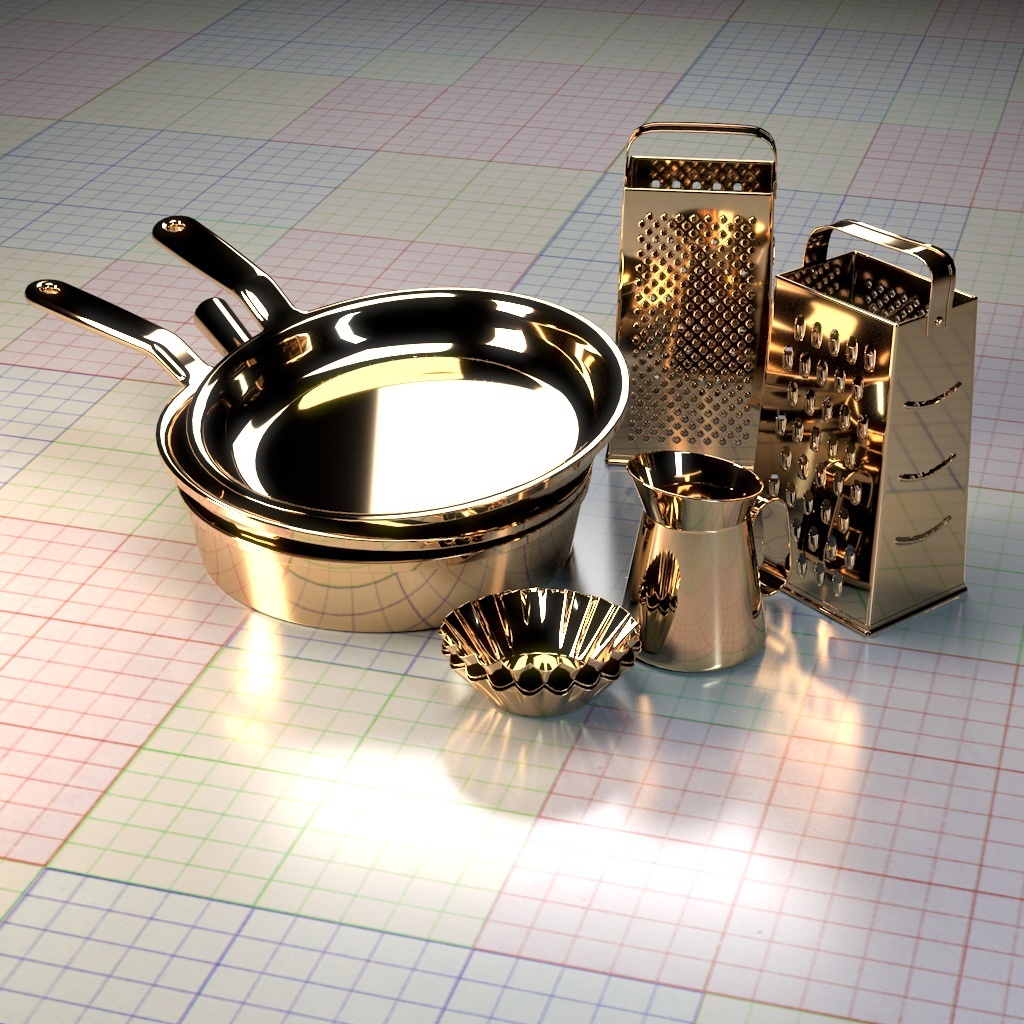

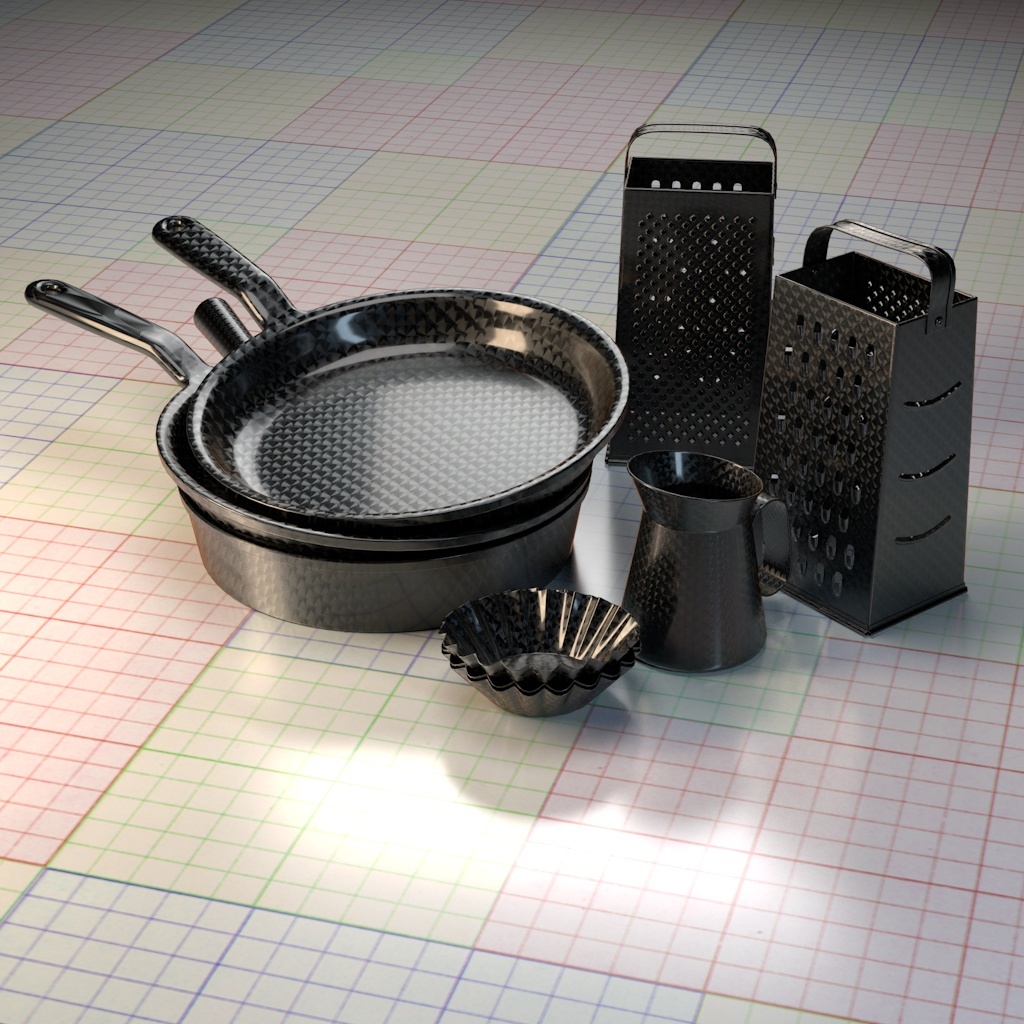

The following images show some of the presets available through the Attribute Editor.

CopperReflectivity [0.9466, 0.6, 0.5382] | GoldReflectivity [ 0.8841, 0.6009, 0.3480] |

AluminiumReflectivity [ 0.9094, 0.8889, 0.8715] | IronReflectivity [ 0.5351, 0.5109, 0.4958] |

SilverReflectivity [ 0.9521, 0.9246, 0.8911] | CarbonReflectivity [ 0.1542, 0.1395, 0.1312] |

Technical Description

Tempering (thin-film interference)

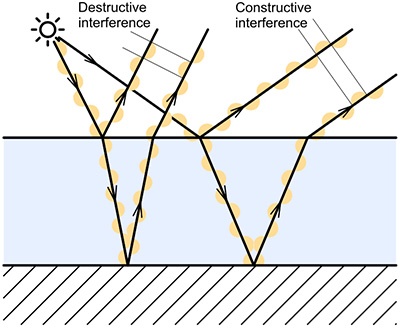

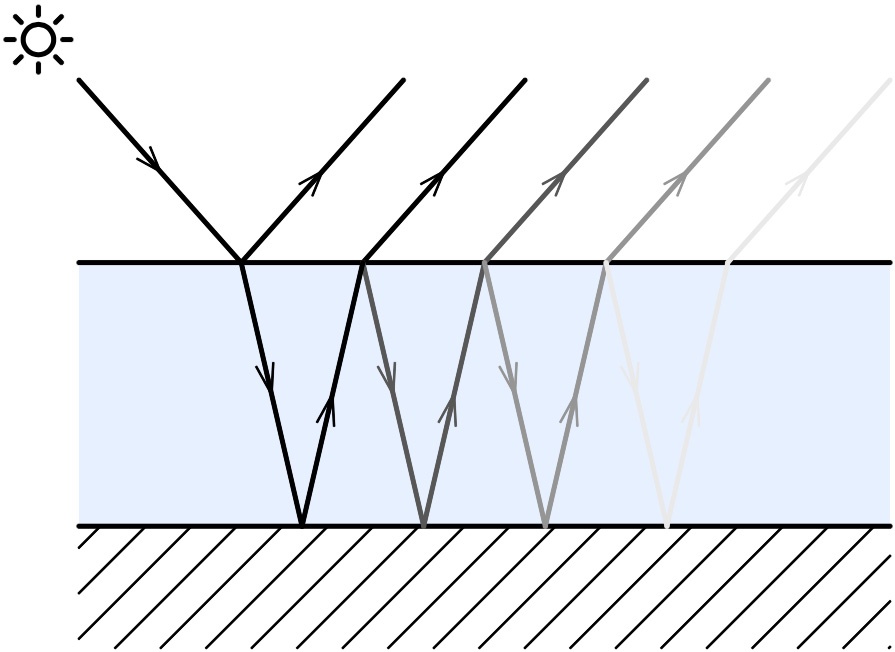

Interference colours are produced when metal is heated and a thin film of metal's oxide forms on the surface. They are dependent on the wavelength and angle of the incident light, the thickness of the oxide film and the refractive indices of the oxide material. This effect is also called thin-film interference .

Figure 1: Explanation of thin-film interference. When the phase difference between the two reflected beams is an even integer multiple of the wavelength of the beam in the film, then the two reflected beams tend to interfere constructively. If the phase difference between the two reflected beams is an odd integer multiple of the wavelength of light in the film, the beams interfere destructively. | Figure 2: Light path in a thin film of the metal's oxide. |

Tempering vs. Coating

Coating differs from tempering in that it is used to render a relatively thick medium that has been applied on top of the metal (such as is the case of car paint). Tempering produces a very thin layer of oxyde on the metal surface which can produces interference.

Anisotropy

From Wikipedia: "In the field of computer graphics, an anisotropic surface changes in appearance as it rotates about its geometric normal, as is the case with velvet".

Anisotropy allows to set a different roughness depending on the orientation on surface. On real world surfaces, anisotropy is generated by microstructure characteristics of the surface. For example, brushed metal objects are polished in such way that there are a lot of parallel scratches on the surface. On CDs, the microstructure is produced by "tracks" describing the actual data. The following video shows the effect of anisotropy coupled with tempering.