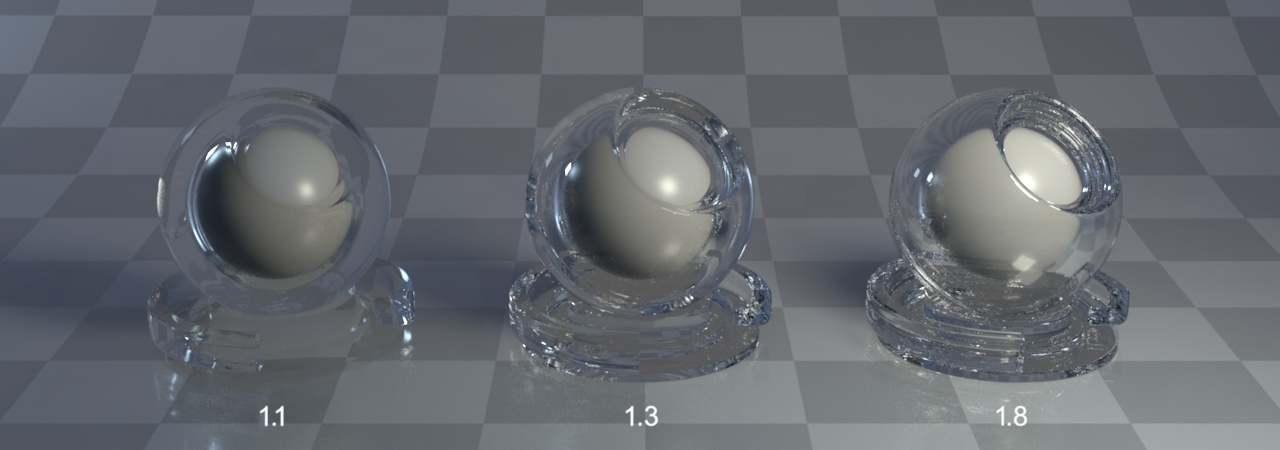

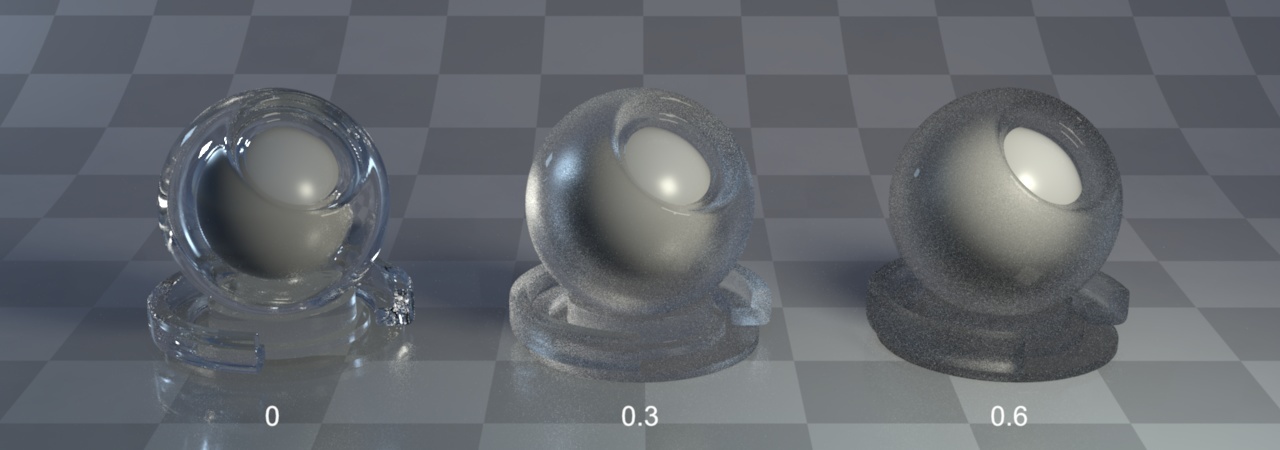

3Delight Glass allows rendering a variety of translucent materials, going from simple coloured glass and translucent plastics down to soap bubbles with complex light interference effects. Under the hood is the production-proven GGX BRDF. The material has two main components: reflection and refraction. Each of these components has it's own roughness and index of refraction. This might appear counter-intuitive but it allows to simulate a variety of interesting surfaces as shown in the parameter description below. As a supplement to these two components, 3Delight Glass can simulate an additional thin film on the top of the surface. This thin film helps simulate real life surfaces such as tainted glass, oxidation and very thin materials. This controls the specular roughness*. The larger the value, the rougher is the surface. A roughness of zero generates mirror reflections.

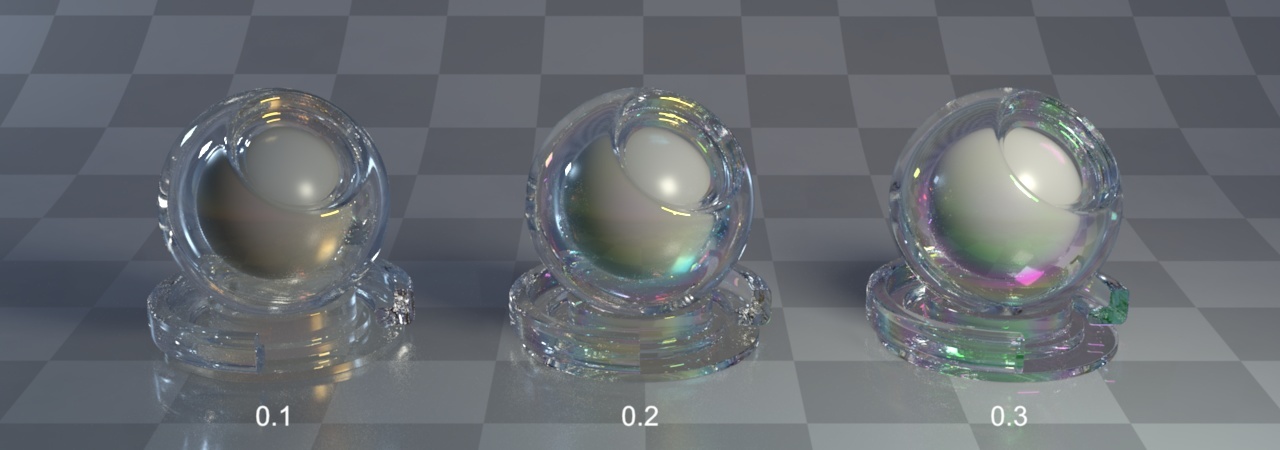

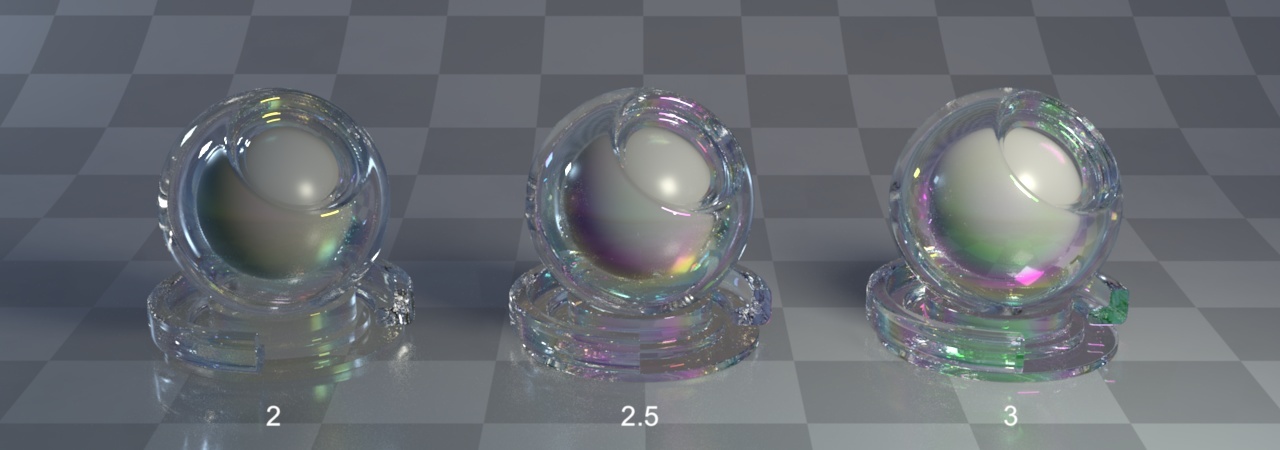

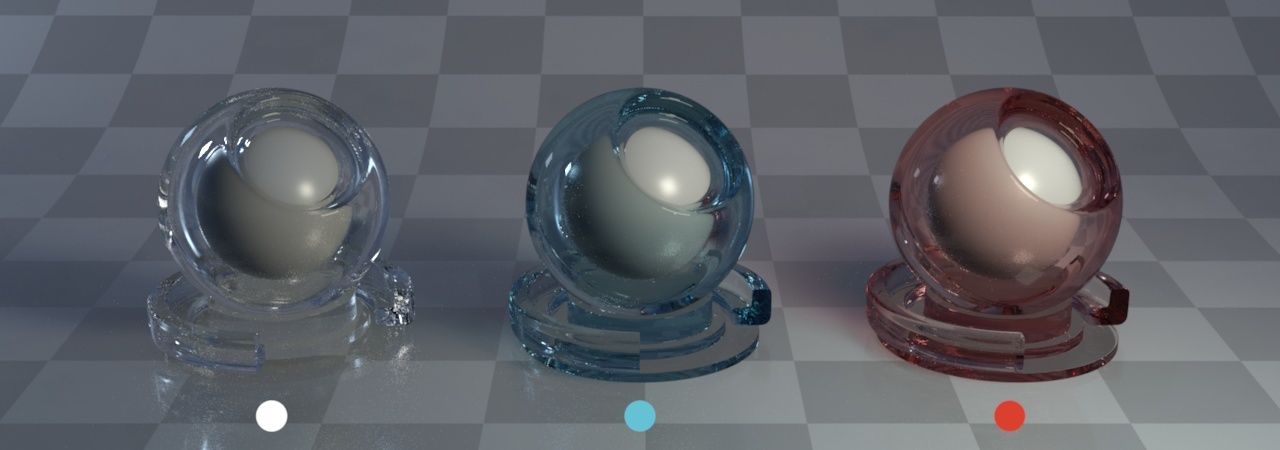

*This is the roughness specified to the GGX BRDF. The index of refraction to use to calculate Fresnel reflections. Higher values generate more prominent specular reflections. Enables thin-film interference. Thin film interference is a complexe phenomena that depends on many variables, including viewing position and usually generates rich patterns on top of the rendered surface. 3Delight performs a physically correct light interference simulation of this phenomena.

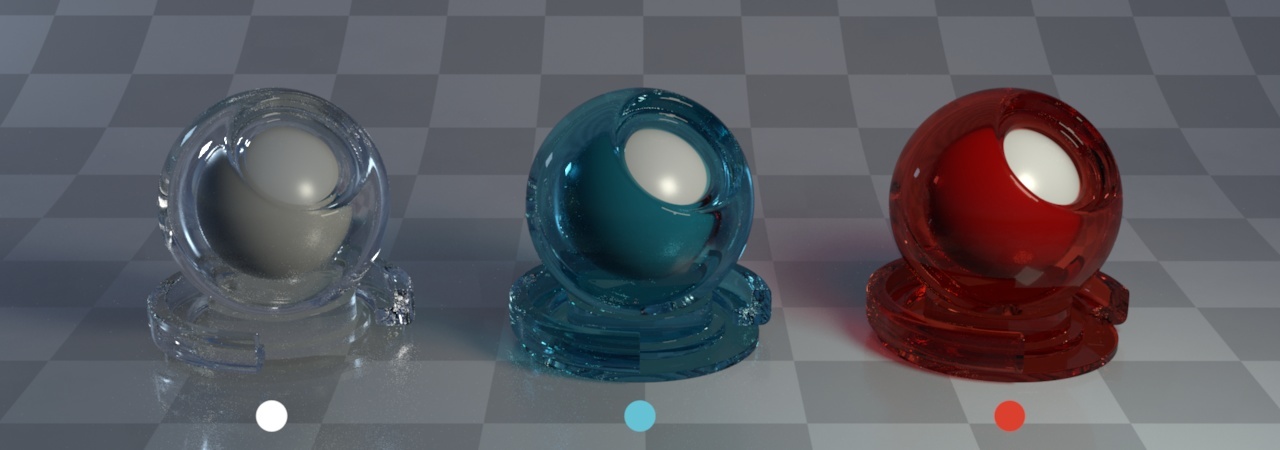

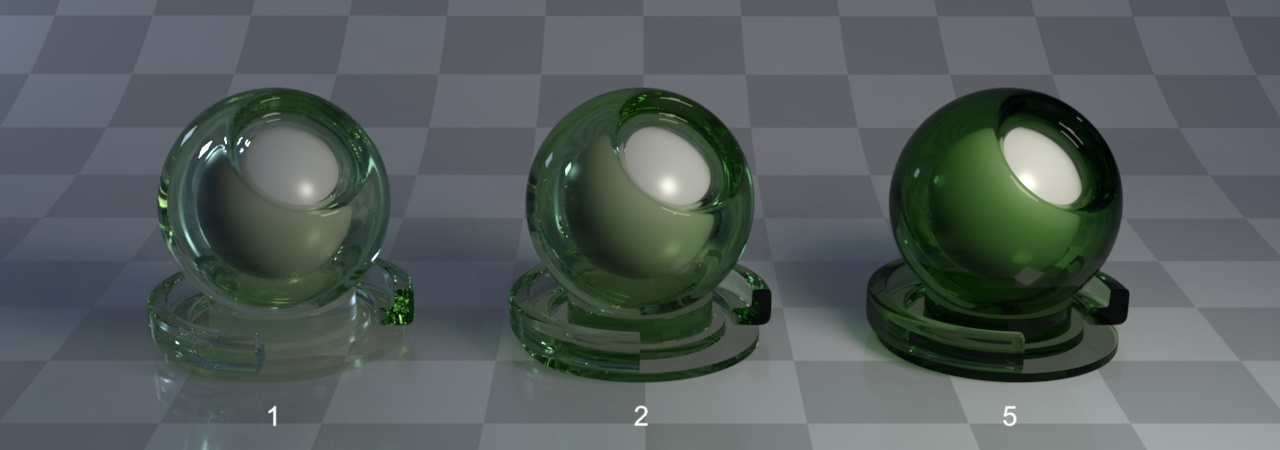

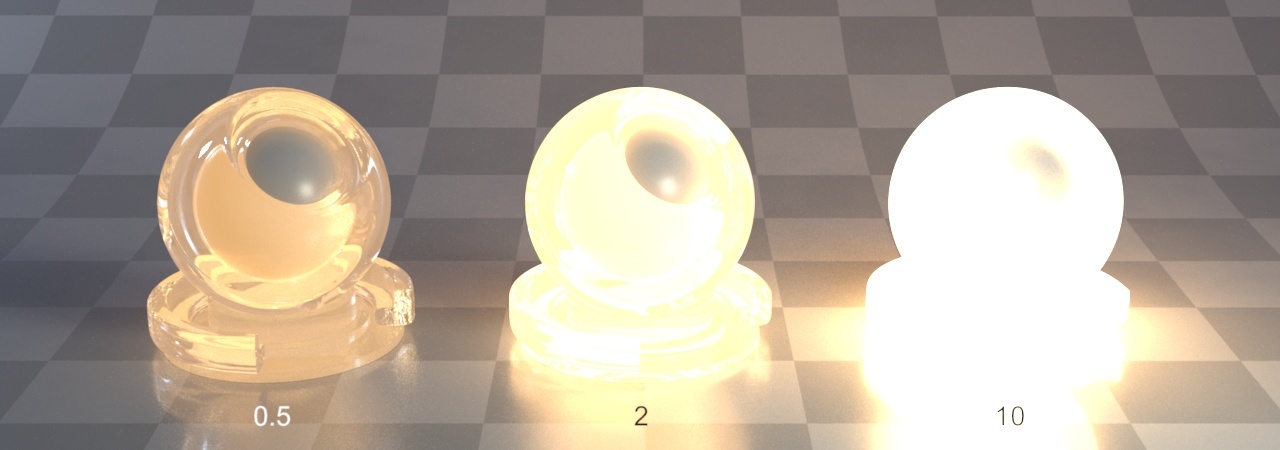

Specifies the thickness of the film in ucm. Sets the index of refraction of the thin film. This value depends on the material of which the thin film is made. Even if specific index of refractions are needed to simulate real life phenomena (e.g. use an index of refraction of 1.458 for the thin film of silicon dioxide formed on glass because of thermal oxidation) one can simply adjust this value to obtain the desired look. Sets the color of the refraction. Setting this color to 0 disables refraction. Sets the roughness of the refraction. The smaller the value, the smoother is the surface. Higher values can be used to emulate "ground glass" and also help emulate more complex material interiors. This parameter is a more user friendly way to specify the absorption of the material. It specifies the colour that passes through the volume. Note how coloration varies with volume thickness, contrary to the refraction color parameter which is constant through the slab. This is due to an exponential falloff in such volumes. Specifies how dense the material is.* *Along with the transmittance above, the physical absorption of the material is calculated as such: physical absorption = density * (1-transmittance). Sets the index of refraction of the translucent surface. We will try to approximate the look of this marble. We definitely need a blue color for the "interior" of the marble. But which parameter to use, Refraction Color or Transmittance ? Since the inside of the marble is solid, Transmittance is the best choice because it will simulate an exponential light falloff. Transmittance = blue with a strength of 2.3 We can simulate such fuziness by using a Refraction Roughness larger than 0. Reflection Roughness = 0 Simply enable thin-film interference and try to guess the IOR of the thin-film. As an educated guess, we set the IOR to 1.458 which is the index of refraction of silicon dioxide, a material that forms when glass is heated. Not surprisingly, we get a close enough match. Film Thickness = 0.25 ucm So we have a render that has many of the features of the original image. To continue the look development, one can use better lighting, internal object structure (air pockets) and varying thin-film thickness.Parameters Description

Reflection

Color

Specifies the color for reflections. Roughness

There are no images attached to this page. IOR

Thin Film

There are no images attached to this page. Film Thickness

Film IOR

Refraction

Color

Roughness

Transmittance

Density

IOR

Incandescence Color Incandescence intensity Lookdev Example: Marbles

Observation Relationship to 3Delight Glass Parameters Render The marble is made of glass and has both reflection and refractions (transparent). We choose an IOR of 1.3 ("light" glass) for both reflection and refraction and dial in the same color for both effects. We have and overall bluish color. Note that some part of the marble are still white (reflection of sky).

Refraction Color = leave whiteThe interior of the ball is "fuzzy" while the reflections are mirror-like.

Refraction Roughness = 0.15There is a pink gradient on top of the sphere. This effect is recognizable as thin-film interference. In this case the marble must have some kind of very thin cover or has been heated and an oxide must have formed.

Film IOR = 1.458

Overview

Content Tools